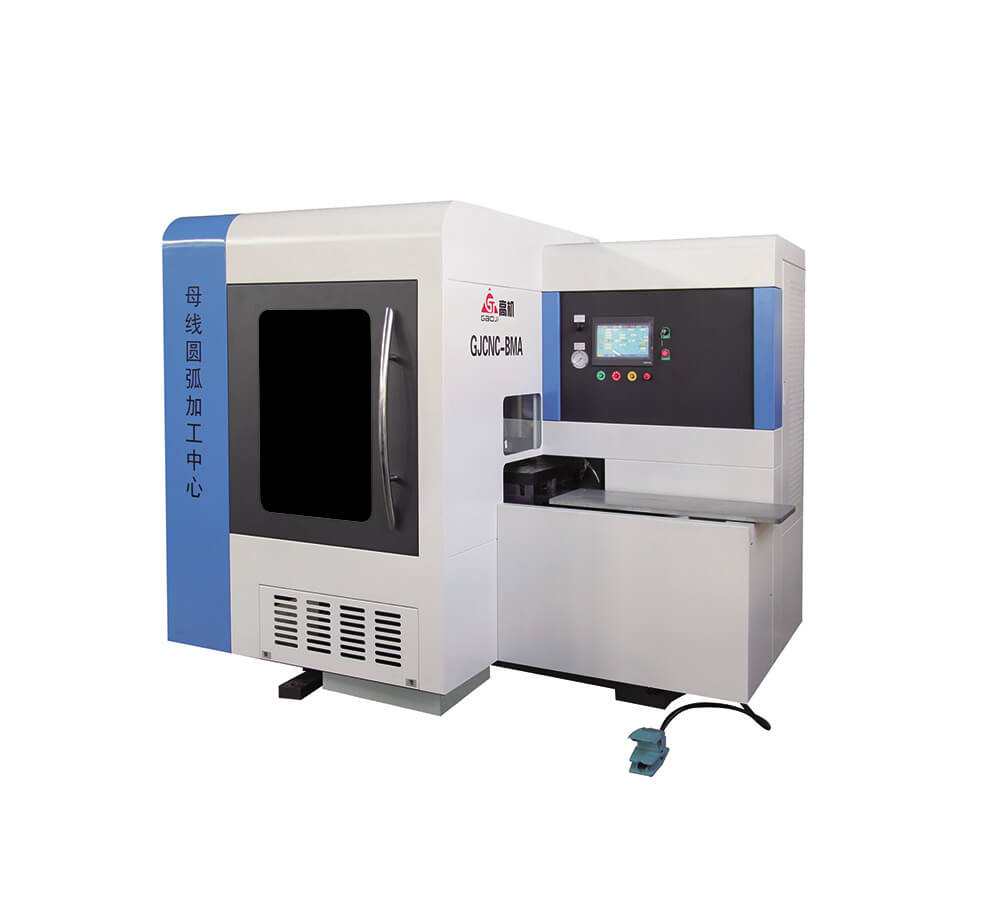

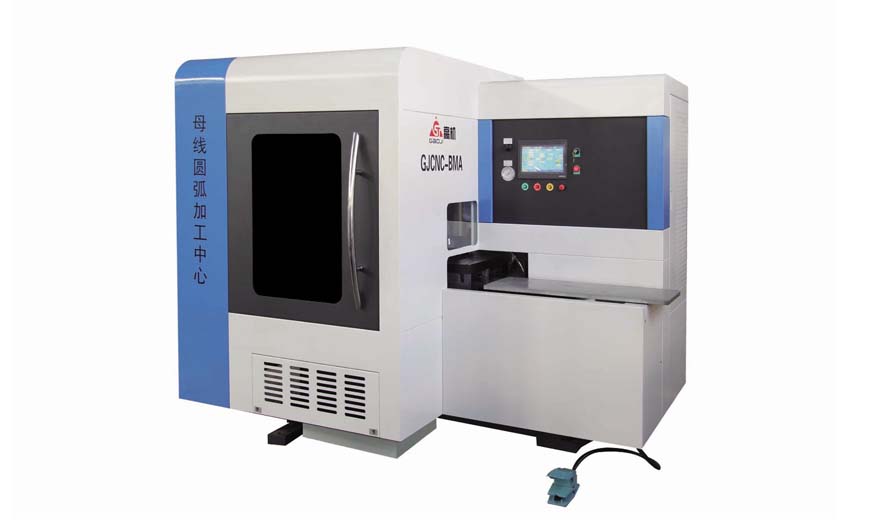

Injin Yankan Lanƙwasa na CNC Mai Inganci

Ƙungiyar ta ci gaba da bin manufar tsarin "sarrafawa a fannin kimiyya, inganci mai kyau da inganci, fifikon masu amfani ga Injin Yanke Busbar Mai Inganci na CNC, Muna maraba da ku da ku kafa haɗin gwiwa da kuma ƙirƙirar kyakkyawar makoma tare da mu.

Ƙungiyar ta ci gaba da bin manufar tsarin "gudanar da kimiyya, inganci mai kyau da inganci, fifikon masu amfani gaInjin Yanke Tagulla na Hydraulic da Injin Sarrafa Arc na ChinaYanzu mun sami karbuwa sosai tsakanin abokan ciniki a ko'ina cikin duniya. Suna amincewa da mu kuma koyaushe suna ba da umarni akai-akai. Bugu da ƙari, an ambata a ƙasa wasu daga cikin manyan abubuwan da suka taka muhimmiyar rawa a cikin babban ci gabanmu a wannan fanni.

Cikakkun Bayanan Samfura

Injin niƙa busbar na CNC galibi yana aiki ne a cikin niƙa fillet da babban fillet a cikin busbar. Yana samar da lambar shirin ta atomatik kuma yana aika lambar zuwa kayan aiki bisa ga buƙatun da ke kan bayanin busbar da shigar da bayanai akan allon nuni. Yana da sauƙin aiki kuma yana iya sarrafa baka mai amfani da busbar tare da kyakkyawan kyan gani.

Riba

Ana amfani da wannan injin don yin aikin injinan sassaka na baka don kawunan sandunan bus tare da H≤3-15mm, w≤140mm da L≥280mm.

Za a yi wa kan sandar injin gyaran siffar da tsari mai kyau.

Maƙallan suna amfani da fasahar tsakiya ta atomatik don danna kan matsi mafi kyau akan wurin ɗaukar ƙarfi.

Ana amfani da na'urar ƙara ƙarfi a kan kan matsewa don tabbatar da kwanciyar hankalin kayan aikin, wanda hakan zai sa ya fi kyau a yi amfani da injin.

Ana amfani da na'urar riƙe kayan aiki ta BT40 ta duniya don sauƙin maye gurbin ruwan wukake, tauri mai kyau da kuma daidaito mai girma.

Wannan injin yana amfani da sukuran ƙwallon da aka yi daidai da kuma jagororin layi. An zaɓi manyan layukan jagora masu nauyi don samar da ingantaccen tauri ga dukkan injin, rage girgiza da hayaniya, inganta ingancin kayan aikin da kuma tabbatar da daidaito da inganci mai kyau.

Ta amfani da sassan samfuran gida da na duniya, wannan injin yana da tsawon rai na aiki kuma yana iya tabbatar da inganci mai kyau.

Shirin da ake amfani da shi a cikin wannan injin shine software na shirye-shiryen zane-zane na atomatik da kamfaninmu ya haɓaka, wanda ke fahimtar sarrafa kansa a cikin shirye-shiryen shirye-shirye. Mai aiki ba dole ba ne ya fahimci lambobi daban-daban, kuma ba dole ba ne ya san yadda ake gudanar da cibiyar injin gargajiya. Mai aiki kawai dole ne ya shigar da sigogi da yawa ta hanyar komawa ga zane-zane, kuma kayan aikin za su samar da lambobin injin ta atomatik. Yana ɗaukar ɗan gajeren lokaci fiye da shirye-shiryen hannu kuma yana kawar da yuwuwar kuskuren lambar da shirye-shiryen hannu ke haifarwa.

Motar bas da aka ƙera a cikin wannan injin tana da kyau, ba tare da fitar da ruwa ba, tana rage girman kabad don adana sarari kuma tana rage yawan amfani da jan ƙarfe sosai.

Ƙungiyar ta ci gaba da bin manufar tsarin "sarrafawa a fannin kimiyya, inganci mai kyau da inganci, fifikon masu amfani ga Injin Yanke Busbar Mai Inganci na CNC, Muna maraba da ku da ku kafa haɗin gwiwa da kuma ƙirƙirar kyakkyawar makoma tare da mu.

Babban InganciInjin Yanke Tagulla na Hydraulic da Injin Sarrafa Arc na ChinaYanzu mun sami karbuwa sosai tsakanin abokan ciniki a ko'ina cikin duniya. Suna amincewa da mu kuma koyaushe suna ba da umarni akai-akai. Bugu da ƙari, an ambata a ƙasa wasu daga cikin manyan abubuwan da suka taka muhimmiyar rawa a cikin babban ci gabanmu a wannan fanni.

Saita

| Girma (mm) | Nauyi (kg) | Girman Teburin Aiki (mm) | Tushen Iska (Mpa) | Jimlar Ƙarfi (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Sigogi na Fasaha

| Ƙarfin Moter (kw) | 7.5 | Ƙarfin Aiki (kw) | 2*1.3 | Max Torpue (Nm) | 62 |

| Samfurin Mai Riƙe Kayan Aiki | BT40 | Diamita na Kayan Aiki (mm) | 100 | Gudun Dogon Ƙafa (RPM) | 1000 |

| Faɗin Kayan Aiki (mm) | 30~140 | Matsakaicin Tsawon Kayan Aiki (mm) | 110 | Kauri na Kayan Aiki (mm) | 3~15 |

| X-Axis Stoke (mm) | 250 | Y-Axis Stoke (mm) | 350 | Saurin Matsayi Mai Sauri (mm/min) | 1500 |

| Fitowar Ballscrew (mm) | 10 | Daidaiton Matsayi (mm) | 0.03 | Saurin Ciyarwa (mm/min) | 1200 |