Babban injin yanke bututun CNC na China

Muna bin ƙa'idar gudanarwa ta "Inganci abin birgewa ne, Ayyuka suna da matuƙar kyau, Matsayi shine farko", kuma da gaske za mu ƙirƙiri da raba nasara tare da duk abokan ciniki don Injin Rage Busbar na CNC Punching Shearing Machinery, Tare da bin falsafar kasuwanci ta 'abokin ciniki da farko, ci gaba', muna maraba da masu siyayya daga gida da waje don yin aiki tare da mu.

Muna bin ƙa'idar gudanarwa ta "Inganci abin mamaki ne, Ayyuka suna da matuƙar muhimmanci, Matsayi shine farko", kuma za mu ƙirƙiri da kuma raba nasara tare da duk abokan ciniki donInjin Busbar, Injin Rasa Busbar na ChinaShekaru da yawa na gogewa a aiki, yanzu mun fahimci mahimmancin samar da kayayyaki da mafita masu inganci da mafi kyawun ayyuka kafin siyarwa da bayan siyarwa. Yawancin matsalolin da ke tsakanin masu samar da kayayyaki da abokan ciniki suna faruwa ne saboda rashin kyawun sadarwa. A al'adance, masu samar da kayayyaki na iya yin jinkirin yin tambayoyi game da abubuwan da ba su fahimta ba. Muna warware waɗannan shingen don tabbatar da cewa kun sami abin da kuke so zuwa matakin da kuke tsammani, lokacin da kuke so. Lokacin isarwa da sauri kuma samfurin da kuke so shine Ma'auninmu.

Cikakkun Bayanan Samfura

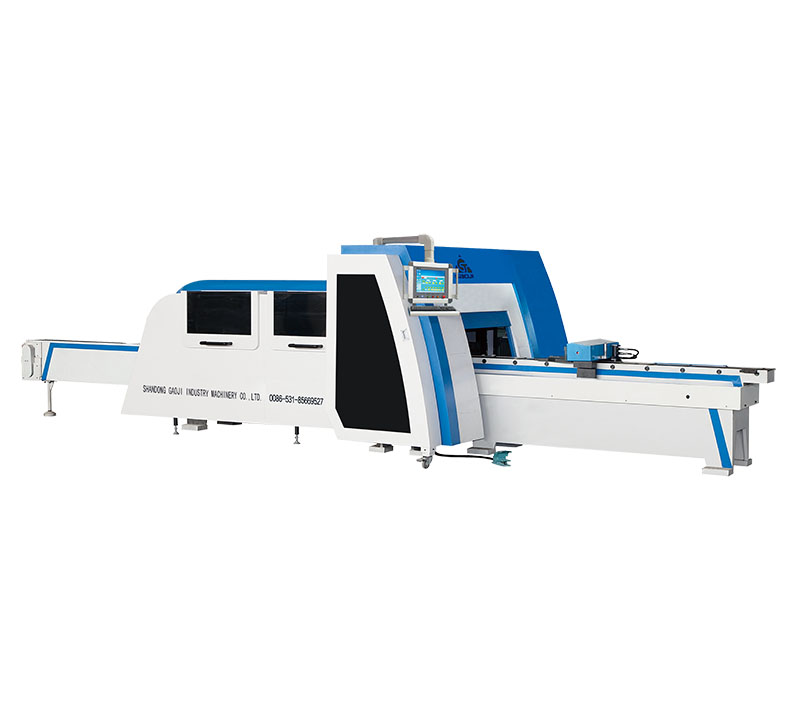

GJCNC-BP-50 kayan aiki ne na ƙwararru waɗanda aka ƙera don sarrafa sandar bus cikin inganci da daidaito.

A lokacin sarrafa wannan kayan aiki na iya maye gurbin maƙallan ta atomatik, wanda ke da matuƙar tasiri musamman ga dogon sandar bus. Tare da waɗannan maƙallan sarrafawa a cikin ɗakin karatu na kayan aiki, wannan kayan aikin zai iya sarrafa sandar bus ta hanyar naushi (rami mai zagaye, rami mai faɗi da sauransu), embossing, asking, grooving, yanke kusurwar filleted da sauransu. Mai jigilar kaya zai kawo kayan aikin da aka gama.

Wannan kayan aiki zai iya dacewa da layin samar da injin CNC da kuma bututun sarrafa bututun.

Babban Jarumi

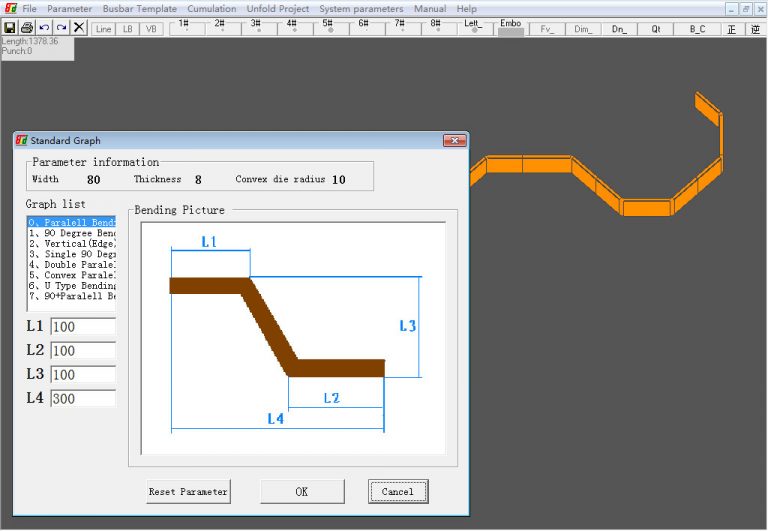

GJ3D / software na shirye-shirye

GJ3D software ne na musamman da aka taimaka wa wajen tsara tsarin sarrafa bas. Wanda zai iya shirya lambar na'ura ta atomatik, ƙididdige kowace rana a cikin sarrafawa, kuma ya nuna maka kwaikwayon dukkan tsarin wanda zai gabatar da canjin bas mataki-mataki a sarari. Waɗannan haruffan sun sa ya zama mai sauƙi da ƙarfi don guje wa rikitarwar lambar hannu tare da yaren injin. Kuma yana iya nuna dukkan tsarin kuma ya hana ɓarnar kayan ta hanyar shigar da ba daidai ba.

Tsawon shekaru da suka gabata, kamfanin ya jagoranci amfani da fasahar zane ta 3D a masana'antar sarrafa busbar. Yanzu za mu iya gabatar muku da mafi kyawun software na sarrafa CNC da ƙira a Asiya.

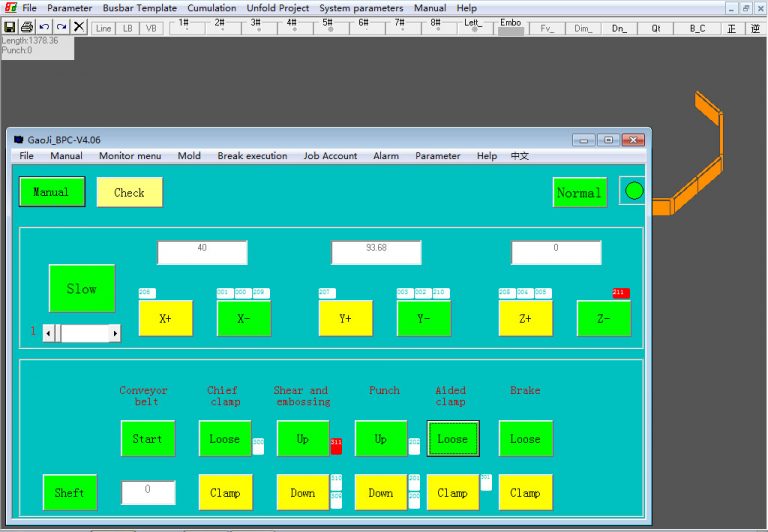

Haɗin kwamfuta na ɗan adam

Domin gabatar da ingantaccen ƙwarewar aiki da ƙarin bayani mai amfani. Kayan aikin yana da hanyar sadarwa ta RMTP mai inci 15 a matsayin hanyar sadarwa ta ɗan adam da kwamfuta. Tare da wannan na'urar, zaku iya samun bayanai dalla-dalla game da dukkan tsarin ƙera ko duk wani ƙararrawa da zai iya faruwa, sannan ku sarrafa kayan aikin da hannu ɗaya.

Idan kana buƙatar gyara bayanan saitin kayan aiki ko sigogin ma'aunin ...

Tsarin Inji

Domin ƙirƙirar tsari mai inganci, daidaito, da tsawon rai na injiniya, mun zaɓi sukurin ƙwallo mai inganci, jagorar layi mai daidaito ta Taiwan HIWIN da tsarin servo ta YASKAWA tare da tsarin matsewa guda biyu na musamman. Duk waɗannan da ke sama suna ƙirƙirar tsarin watsawa kamar yadda kuke buƙata.

Muna haɓaka shirin maye gurbin atomatik don inganta tsarin matsewa musamman don dogon sarrafa bas, kuma yana iya rage aikin mai aiki sosai. Ƙirƙiri ƙarin ƙima ga abokin cinikinmu.

Akwai nau'i biyu:

GJCNC-BP-50-8-2.0/SC (Naushi shida, yankewa, da kuma matsewa)

GJCNC-BP-50-8-2.0/C (Hunƙusa takwas, yankewa ɗaya)

Za ka iya zaɓar samfuran da kake buƙatar

Fitar da Fitarwa

Muna bin ƙa'idar gudanarwa ta "Inganci abin birgewa ne, Ayyuka suna da matuƙar kyau, Matsayi shine farko", kuma da gaske za mu ƙirƙiri da raba nasara tare da duk abokan ciniki don Injin Rage Busbar na CNC Punching Shearing Machinery, Tare da bin falsafar kasuwanci ta 'abokin ciniki da farko, ci gaba', muna maraba da masu siyayya daga gida da waje don yin aiki tare da mu.

Babban injin lanƙwasa na Busbar na China,Injin BusbarShekaru da yawa na gogewa a aiki, yanzu mun fahimci mahimmancin samar da kayayyaki da mafita masu inganci da mafi kyawun ayyuka kafin siyarwa da bayan siyarwa. Yawancin matsalolin da ke tsakanin masu samar da kayayyaki da abokan ciniki suna faruwa ne saboda rashin kyawun sadarwa. A al'adance, masu samar da kayayyaki na iya yin jinkirin yin tambayoyi game da abubuwan da ba su fahimta ba. Muna warware waɗannan shingen don tabbatar da cewa kun sami abin da kuke so zuwa matakin da kuke tsammani, lokacin da kuke so. Lokacin isarwa da sauri kuma samfurin da kuke so shine Ma'auninmu.

Babban Sigogi na Fasaha

| Girma (mm) | 7500*2980*1900 | Nauyi (kg) | 7600 | Takardar shaida | CE ISO | ||

| Babban Ƙarfin (kw) | 15.3 | Voltage na Shigarwa | 380/220V | Tushen Wutar Lantarki | Na'ura mai aiki da karfin ruwa | ||

| Ƙarfin Fitarwa (kn) | 500 | Saurin Naushi (hpm) | 120 | Tsarin Sarrafawa | 3 | ||

| Matsakaicin Girman Kayan Aiki (mm) | 6000*200*15 | Mafi girman naushi | 32mm (Kauri na kayan ƙasa da 12mm) | ||||

| Saurin Wuri(X axis) | 48m/min | Buga Silinda Mai Naushi | 45mm | Maimaita Matsayi | ±0.20mm/m | ||

| Mafi girman bugun jini(mm) | X AxisAxis YZ Axis | 2000530350 | AdadinofMutuwa | NausheRasaƘarfafawa | 6/81/11/0 | ||

Saita

| Sassan Sarrafa | Sassan Watsawa | ||

| Kamfanin PLC | OMRON | Jagorar Layi Mai Daidaito | HIWIN na Taiwan |

| Na'urori masu auna sigina | Schneider lantarki | Daidaito na sukurorin ƙwallon (jeri na 4) | HIWIN na Taiwan |

| Maɓallin Sarrafa | OMRON | Ƙwallon ƙwallon tallafi | NSK na Japan |

| Kariyar tabawa | OMRON | Sassan Na'ura mai aiki da karfin ruwa | |

| Kwamfuta | Lenovo | Babban matsin lamba na lantarki mai maganadisu | Italiya |

| Mai haɗa AC | ABB | Bututun mai matsin lamba mai yawa | Italiya MANULI |

| Mai Katse Wutar Lantarki | ABB | Famfon mai matsin lamba mai yawa | Italiya |

| Motar Servo | YASKAWA | Software na sarrafawa da software na tallafi na 3D | GJ3D (manhajar tallafi ta 3D da kamfaninmu ya tsara) |

| Direban Servo | YASKAWA | ||